This month’s issue of Contractor magazine took a special look at the Saniflo SANIBEST above-floor plumbing system, which proved to be the perfect solution for a very expensive drainage dilemma facing a Kansas non-profit.

Earlier this year, manufacturing engineer Thomas Tittel bought a large ranch home to house an innovative addiction recovery program. Unfortunately he only found out later that the home lacked the proper plumbing necessary to accommodate the 10 planned renters from Oxford House, a transitional housing program for recovering alcoholics and addicts.

A basement bathroom had been roughed in, but it would have cost Tittel $2,500 to install the necessary sewage ejector pit and pump to be sure that the water flowed properly. A solution to this costly problem was proposed by a local plumbing rep, Brett Bartlik, who recommended the Saniflo SANIBEST heavy-duty grinding system.

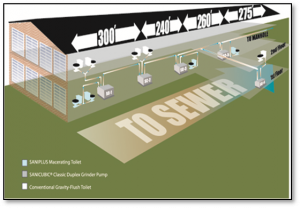

Above-floor grinding and macerating systems like the SANIBEST allow homeowners to install a bathroom virtually anywhere without breaking through the floors, which is particularly helpful when dealing with a concrete basement floor. Rather than routing waste and water down through a floor drain, the Saniflo macerating systems pump effluent up through a narrow discharge line to a soil stack or septic tank. The SANIBEST system was installed in the house’s basement in just three hours. Local Saniflo reps arranged to donate the system to Oxford House in support of their work in the community, but if Tittel had paid for the SANIBEST, he would’ve spent less than half the cost of installing a traditional drainage system.