- Oct

- 7

Posted on October 7, 2012 by John OReilly

Architect’s rendering of new Exploratorium, opening in 2013.

When the new Exploratorium museum — now in the final stages of construction on San Francisco’s waterfront — becomes fully operational in the spring of 2013, its goal is to become the largest net-zero energy museum in the United States, if not the world. (A “net zero-energy” building produces as much energy as it consumes.)

The subject of a cover story in the September 2012 issue of PM Engineer magazine (pme), this massive gut-renovation project at the 800-foot-long Pier 15 aims to be 57 percent more efficient than the ASHRAE 90.1 baseline standard for a typical museum. Among its green innovations are a 1.3 megawatt-AC, photovoltaic solar-panel system, providing all of the structure’s electricity; and a crosslinked polyethylene (PEX) radiant tubing system that uses the San Francisco Bay as a giant heat sink and heat source to warm or cool the building.

The 200,000-foot network of PEX tubing, manufactured by Uponor, is embedded in concrete slabs on two levels and spans 82 different heating-cooling zones. Each zone has a control valve and a thermostat to switch between heating and cooling, whatever the seasonal need. No other type of water-heating equipment is used in the building, nor is there any use of fossil fuels except for highly limited cooking purposes in a small restaurant.

“We did not wish to sacrifice comfort for energy savings on this project, and radiant is a premium comfort system,” says project manager Joe Wenisch of the Integral Group, the mechanical, electrical and plumbing engineer on the project. Radiant technology was an especially good fit with the Exploratorium’s open exhibit space, featuring 30- to 40-foot-high ceilings.

“Radiant allows us to heat and cool at the floor level where the people are, rather than attempting to condition such a large volume of air in those high-ceiling rooms,” he says.

For more information, visit http://www.uponorpro.com/Marketing-and-Sales/Case-Studies/Case-Study-Search.aspx

- Jun

- 29

Posted on June 29, 2012 by Joel Williams

This amazing transformation demonstrates the results from one application of Wet & Forget outdoor cleaner. No scrubbing or powerwashing was needed: Wet & Forget did all the work over three months.

The amazing results with the environmentally gentle, bleach-free Wet & Forget, a scrub-free exterior stain remover, have rung a bell with Environmental Design + Construction magazine. ED+C recently featured a case study developed by O’Reilly-DePalma that shows how Wet & Forget helped restore the fragile tile roof of an 80 year old bell tower in Bok Tower Gardens, a National Historic Landmark located in Lake Wales, Florida.

The size of the roof - a sprawling 50,000 square feet - combined with the delicacy of the Spanish tiles, which could be damaged by traditional pressure washing, made the restoration of the roof particularly challenging. In just one application, Wet & Forget achieved remarkable results erasing the 11 years of mildew accumulation, without scrubbing and with significantly smaller water use compared to pressure washing.

This case study was previously published by the Cleaning Management Institute.

- Jan

- 25

Posted on January 25, 2012 by Joel Williams

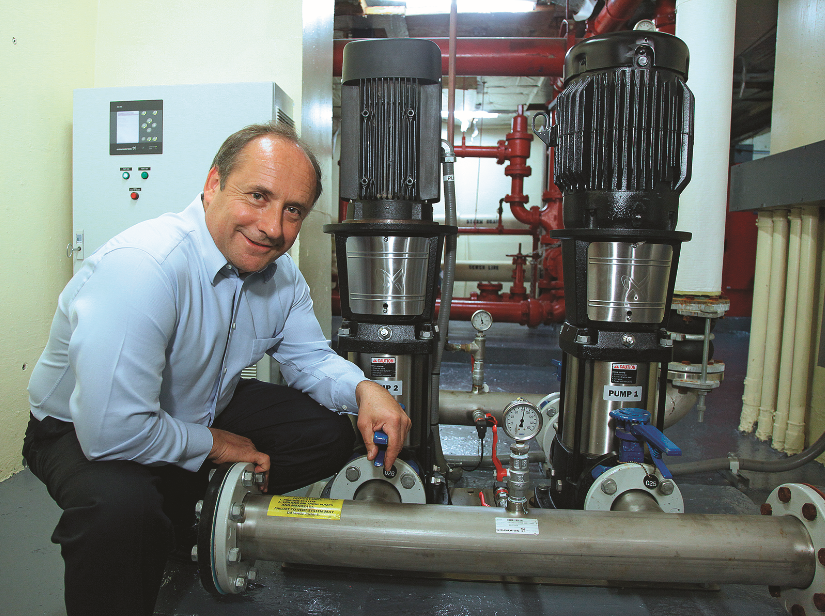

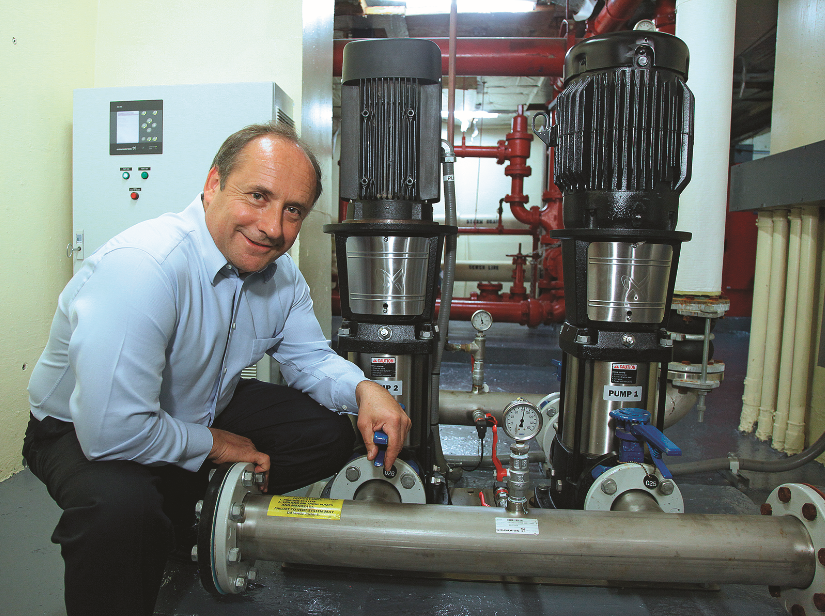

The potential efficiencies of water boosting systems from Grundfos are highlighted in the January cover story of Plumbing Mechanical Engineer, which profiles one apartment building’s jaw-dropping energy savings achieved through variable speed pump technology.

In fact, talk about putting your money where your mouth is- this project’s contractor was so confident in the potential energy savings that he paid for the new system himself — all in an effort to convince building management to invest in the efficient technology.

The gamble paid off in spades.

An independent project audit vindicated the daring claim by documenting a 90 percent energy savings over a one-week period in September 2010, and a 26-month payback period.

Moreover, the drop in power consumption translates to an annual utility cost reduction of nearly $18,160. Total project savings are estimated at $275,000 over the average 15-year pump lifespan. Despite removing 70 HP from this system, the computerized control, demand-based performance of the new pumping station averages just 30 percent capacity.

![Grundfos-CS-Parkview-0079[1]](../../../wp-content/uploads/2012/01/Grundfos-CS-Parkview-00791.jpg)

- Jun

- 1

Commercial radiant temperature control from Uponor is highlighted in this feature article exploring one of Napa Valley’s most prestigious wineries. The article that appeared in the June issue of Environmental Design and Construction Magazine, illustrated why radiant was the only option to deliver the consistent and precise temperature control required for a new winery and barrel cellar. “Temperature control plays a major role in the winemaking process,” explains Kathryn Hall, owner of Hall St. Helena, who notes that the loss of temperature control can ruin an entire batch of wine and would result in a significant loss.

Indeed, the radiant system exceeded expectations, and the project’s environmentally friendly construction recently received the prestigious Gold Leadership in Energy and Environmental Design (LEED®) award. That recognition made Hall St. Helena, the first winery in California to achieve the top certification from the U.S. Green Building Council.

- Jan

- 21

Posted on January 21, 2011 by Joel Williams

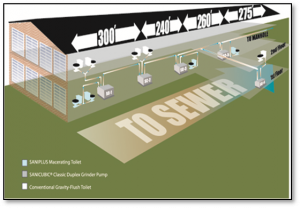

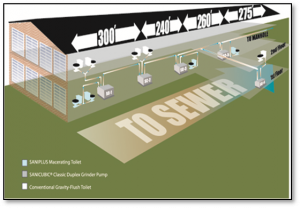

Mechanical Contractor Al Warren overcame the lack of drainage and long sewer line in a historic 19th century industrial building by using an innovative system from SFA Saniflo to pump and process waste without digging.

Mechanical Contractor Al Warren overcame the lack of drainage and long sewer line in a historic 19th century industrial building by using an innovative system from SFA Saniflo to pump and process waste without digging.

The project’s challenge was to tie the 1897 plumbing system into the municipal sanitary sewer system. Making matters worse, contamination was found nearly everywhere, so digging to install new sewer lines and plumbing wasn’t possible either. Plus, the Remington Rand building is 950 feet long – more than three football fields – so the project needed a solution for moving plumbing waste across this expanse plus another 100 feet or so beyond its walls to the sewer main.

The result was the installation of five duplex grinders, positioned at intervals on the ground floor, along the length of the building. This created a “stair effect” that achieved the right pitch in the pipe to accommodate the extreme length of the sewer line.

The result was the installation of five duplex grinders, positioned at intervals on the ground floor, along the length of the building. This created a “stair effect” that achieved the right pitch in the pipe to accommodate the extreme length of the sewer line.

The duplex grinders are installed right on the floor – there is no need to dig. They can handle waste matter from multiple plumbing fixtures, without storing sewage, as sewage ejectors do. Each one pumps effluent up through small diameter pipe into the main and out to the sewer. They work in concert, handling cumulative waste for the entire two-story building.

The case study was featured in the Middletown Press.

![Grundfos-CS-Parkview-0079[1]](../../../wp-content/uploads/2012/01/Grundfos-CS-Parkview-00791.jpg)